Difference between revisions of "Extended baggage"

m |

m |

||

| Line 1: | Line 1: | ||

== Motivation == | == Motivation == | ||

| + | The Bearhawk has great potential to be a hauler of cargo, even more so than as-designed. Another Bearhawk builder friend identified the opportunity to crate the ultimate extended baggage and completed this mod. Visual evidence: | ||

| − | This documented and | + | [[File:Extended baggage.jpg|800px|frameless]] |

| + | |||

| + | This documented and approved modification to the Bearhawk fuselage removes the "V" tubes at the flap cable Y station and replaces them with an inverted dog-leg structure, which allows a large pass-through area. This makes is easier to haul long or bulky items, or even for a person to sleep in the fuselage with the rear seat removed. It necessitates moving the flap "Y" cable routing one station rearward, as well as the of another pulley block. Care should be taken to limit weight at this station for CG considerations, however. | ||

The modification is [https://n813z.bushplanelab.com/images/6/66/Barrows_reply.pdf approved] by Bearhawk designer Bob Barrows. | The modification is [https://n813z.bushplanelab.com/images/6/66/Barrows_reply.pdf approved] by Bearhawk designer Bob Barrows. | ||

| − | |||

| − | |||

=== Tasks === | === Tasks === | ||

| − | # Cut out the V-tubes | + | # Cut out the V-tubes - DONE |

| − | # Clean up the remnants of V tubes and welds | + | # Clean up the remnants of V tubes and welds - PARTIALLY DONE |

| − | # Build and weld in dog-leg structure | + | # Build and weld in dog-leg structure - TO DO |

| − | # Build new pulley bank for next station aft | + | # Build new pulley bank for next station aft - TO DO |

| − | # Build pulley bracket for elevator cable redirect | + | # Build pulley bracket for elevator cable redirect - TO DO |

| − | # Build and weld on new fairleads | + | # Build and weld on new fairleads - TO DO |

| − | # Build and weld on new flap pulley bushings | + | # Build and weld on new flap pulley bushings - TO DO |

===1. Cutting === | ===1. Cutting === | ||

| Line 29: | Line 30: | ||

[[File:Flap-pulley-bushing-smooth.jpg|1200px|frameless|After a lot of delicate grinding]] | [[File:Flap-pulley-bushing-smooth.jpg|1200px|frameless|After a lot of delicate grinding]] | ||

| + | |||

| + | ===3. Dog Leg Structure === | ||

| + | |||

| + | ===4. Add Pulley Bank === | ||

| + | |||

| + | ===5. Add Pulley Bracket for Elevator Cable Redirection === | ||

| + | |||

| + | This bracket and pulleys changes the angle of the cable run to even out the elevator cable tensions. My friend included a DXF file for the weld-on bracket. | ||

Revision as of 08:49, 21 May 2024

Contents

Motivation

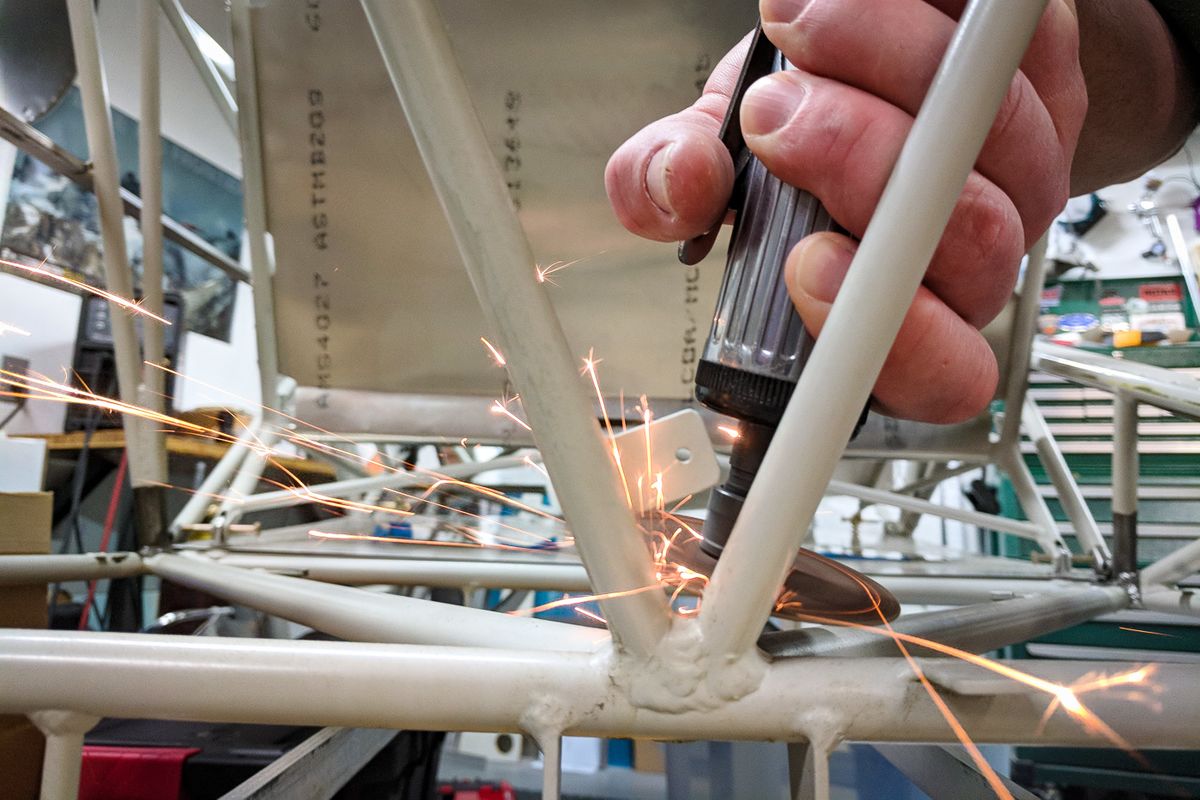

The Bearhawk has great potential to be a hauler of cargo, even more so than as-designed. Another Bearhawk builder friend identified the opportunity to crate the ultimate extended baggage and completed this mod. Visual evidence:

This documented and approved modification to the Bearhawk fuselage removes the "V" tubes at the flap cable Y station and replaces them with an inverted dog-leg structure, which allows a large pass-through area. This makes is easier to haul long or bulky items, or even for a person to sleep in the fuselage with the rear seat removed. It necessitates moving the flap "Y" cable routing one station rearward, as well as the of another pulley block. Care should be taken to limit weight at this station for CG considerations, however.

The modification is approved by Bearhawk designer Bob Barrows.

Tasks

- Cut out the V-tubes - DONE

- Clean up the remnants of V tubes and welds - PARTIALLY DONE

- Build and weld in dog-leg structure - TO DO

- Build new pulley bank for next station aft - TO DO

- Build pulley bracket for elevator cable redirect - TO DO

- Build and weld on new fairleads - TO DO

- Build and weld on new flap pulley bushings - TO DO

1. Cutting

2. Clean up

3. Dog Leg Structure

4. Add Pulley Bank

5. Add Pulley Bracket for Elevator Cable Redirection

This bracket and pulleys changes the angle of the cable run to even out the elevator cable tensions. My friend included a DXF file for the weld-on bracket.