Difference between revisions of "Seats"

From Bearhawk N813Z

m |

m |

||

| Line 1: | Line 1: | ||

After one other failed covering method, I ended up skinning my seat frames in .025 6061. I rolled the edges over to perfectly fit the 3/4" tubing, drilling, and pop riveted them. | After one other failed covering method, I ended up skinning my seat frames in .025 6061. I rolled the edges over to perfectly fit the 3/4" tubing, drilling, and pop riveted them. | ||

| − | + | Daniel from [https://sportaircraftseats.com Sport Aircraft Seats] built the sweetest set of leather Bearhawk seats. Pics later. | |

== Front seats == | == Front seats == | ||

Latest revision as of 17:06, 29 November 2023

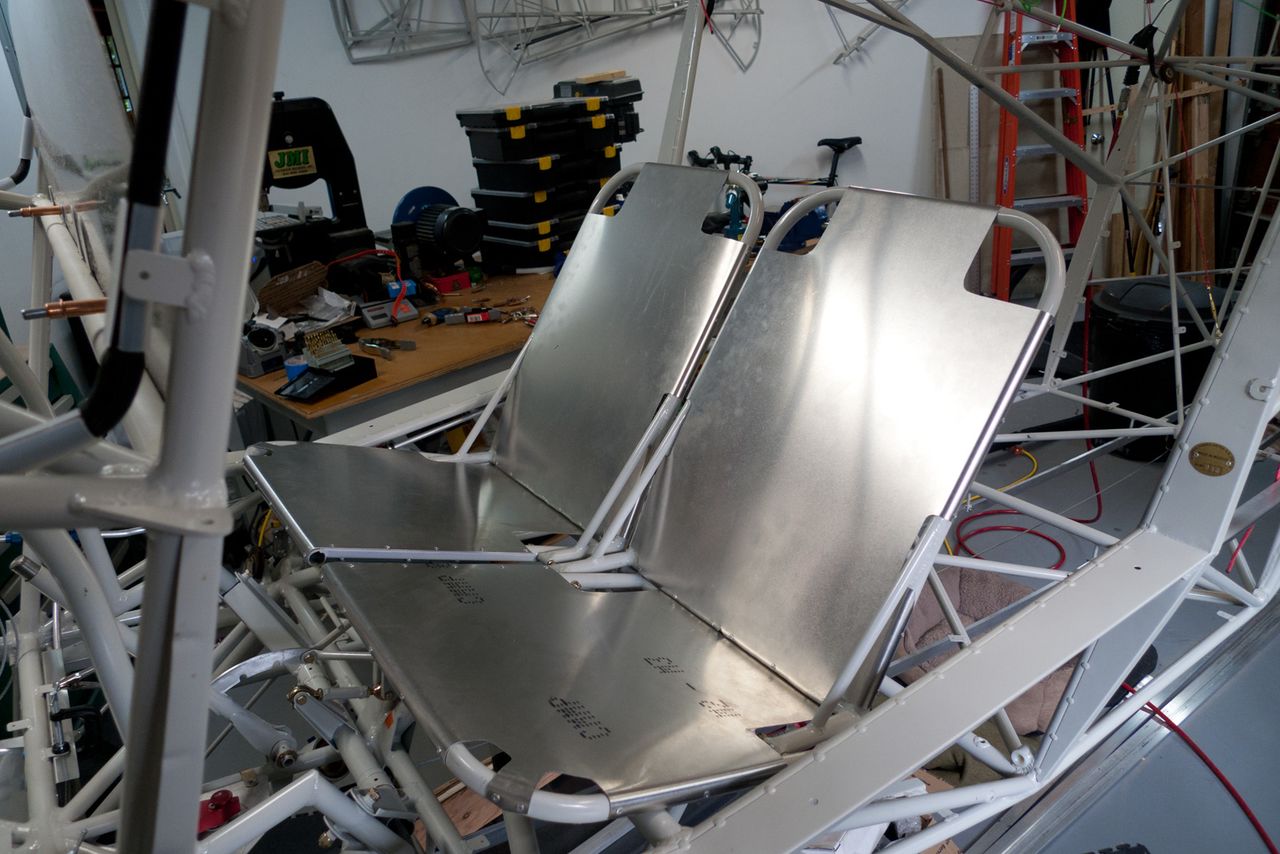

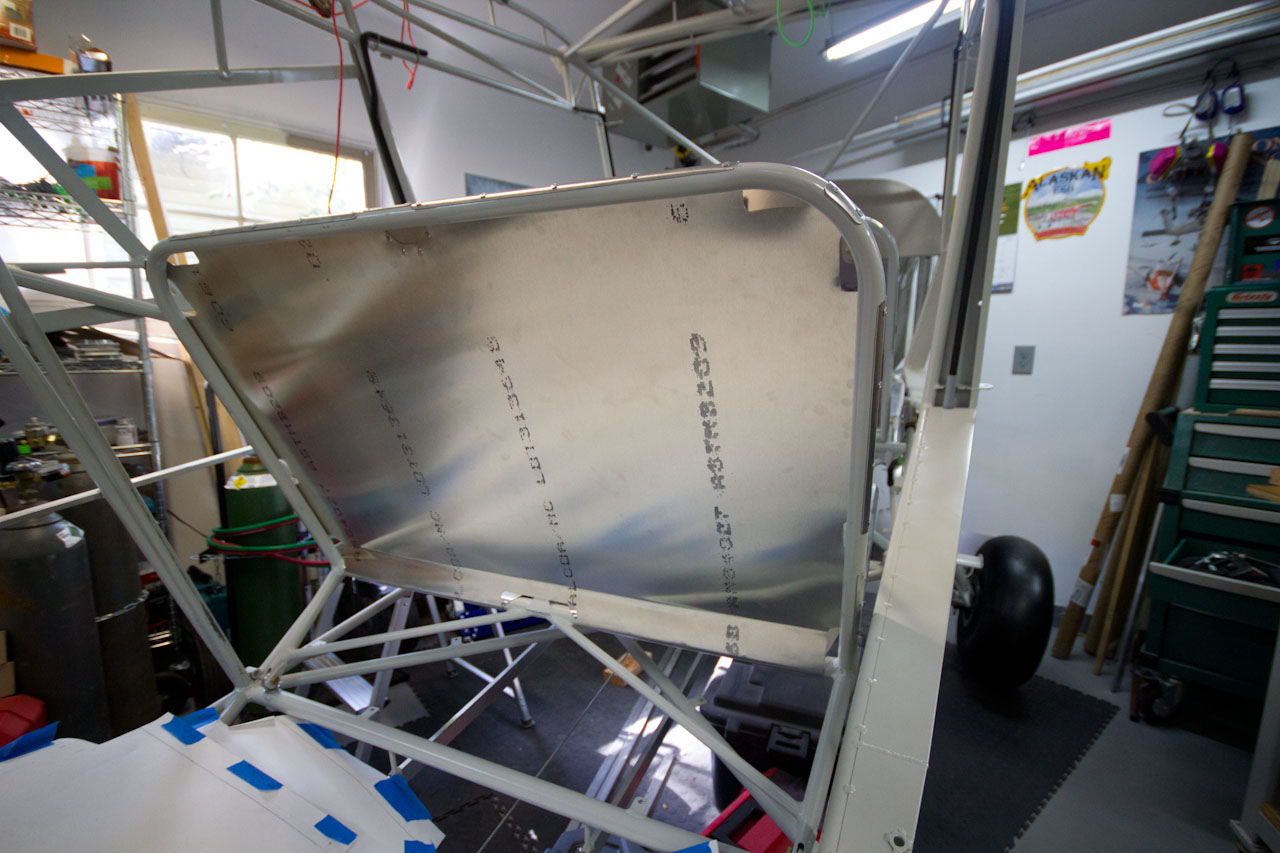

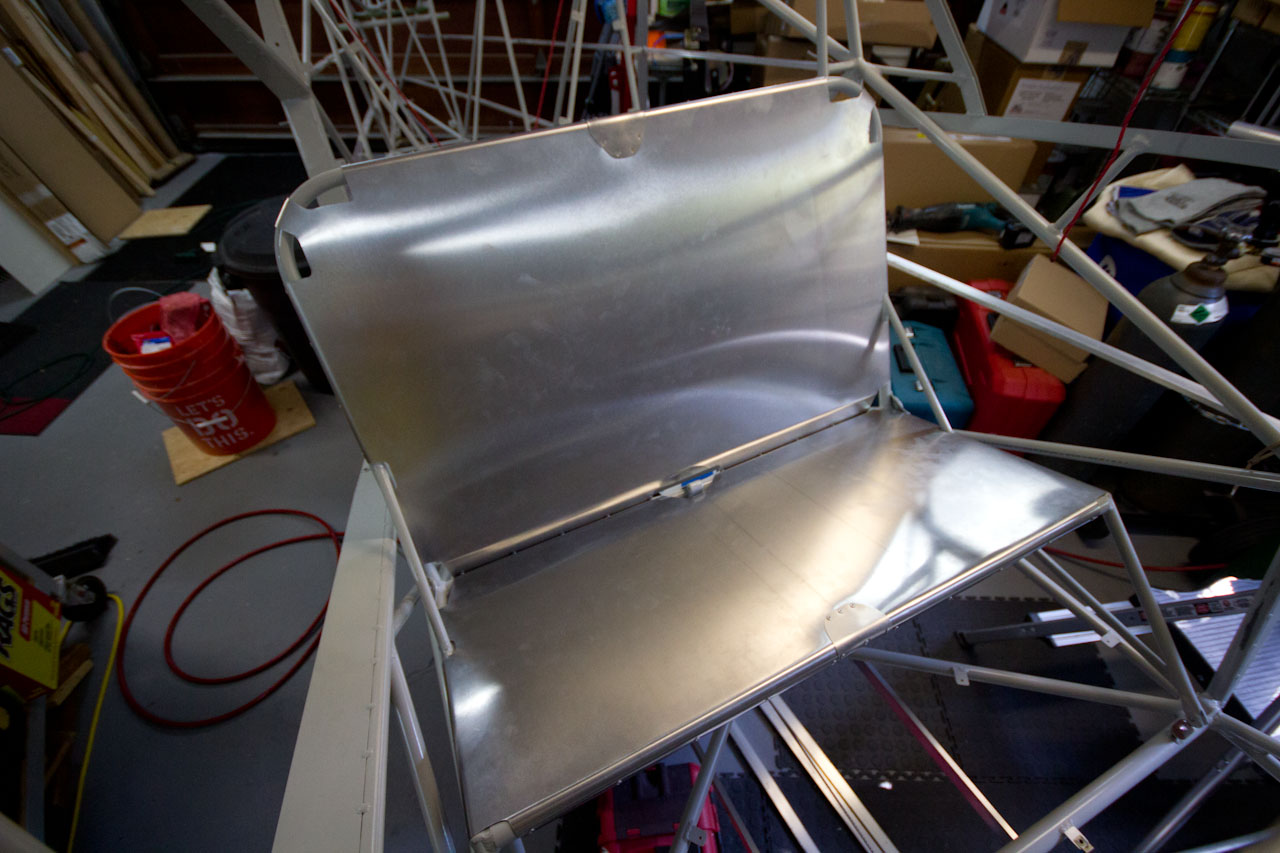

After one other failed covering method, I ended up skinning my seat frames in .025 6061. I rolled the edges over to perfectly fit the 3/4" tubing, drilling, and pop riveted them.

Daniel from Sport Aircraft Seats built the sweetest set of leather Bearhawk seats. Pics later.

Front seats

To do:

- Replace the track nubs with bushing type

- Add doublers to the seat skins at high stress areas.

Rear seats

One issue with the rear seat is the large area of the seat back, which I skinned with lighter .020" 6061, is that it drums easily. I was thinking of using a punch/flare tool to add some lightening holes, which may have the effect of tightening and stiffening the seatback.