Difference between revisions of "Fuel line routing and design"

From Bearhawk N813Z

m |

m |

||

| Line 10: | Line 10: | ||

=== Potential designs: === | === Potential designs: === | ||

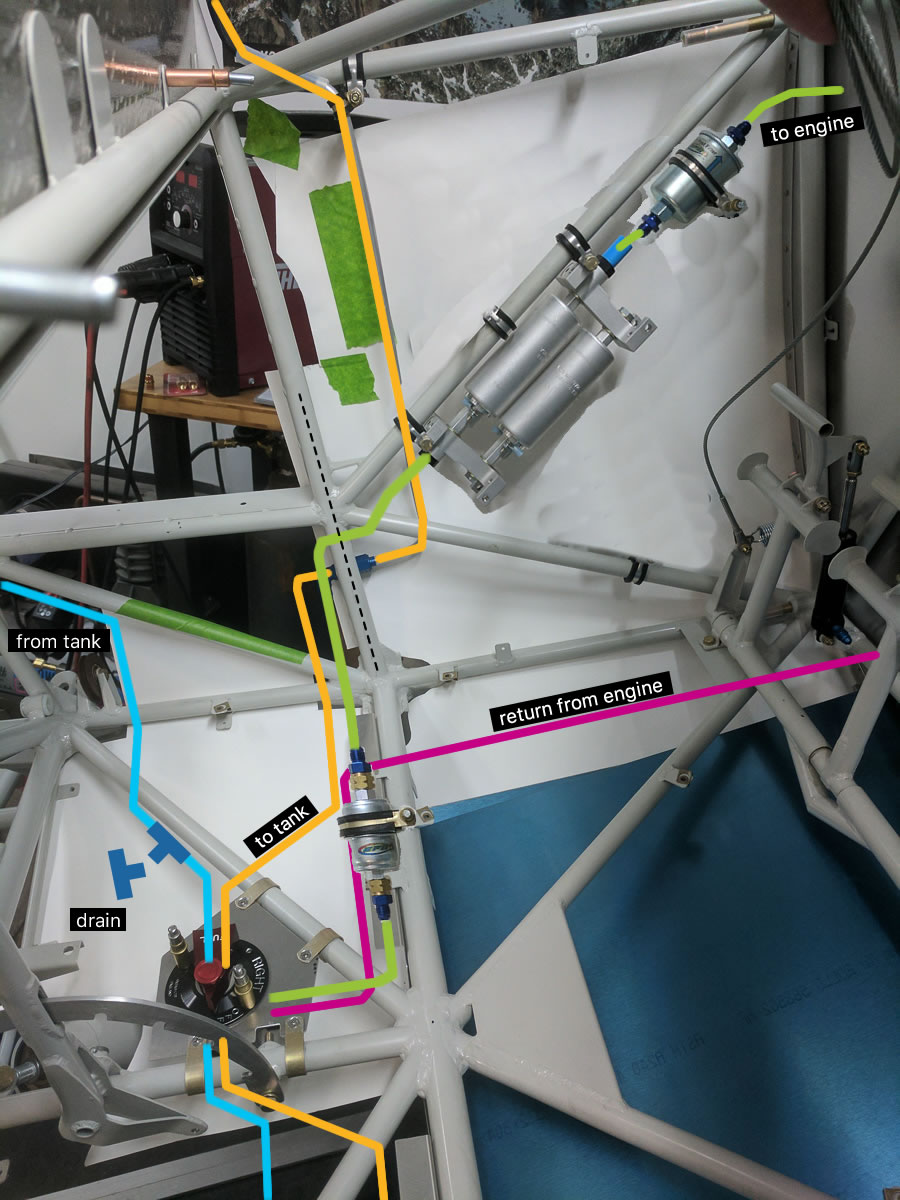

| − | [[File:Fuel-system1.jpeg| | + | [[File:Fuel-system1.jpeg|frame|This is a proposed design that puts the fuel pumps in the boot cowl void. High pressure fuel inside the cabin is not necessarily desirable.]] |

| − | This is a proposed design that puts the fuel pumps in the boot cowl void. High pressure fuel inside the cabin is not necessarily desirable. | ||

| − | [[File:Fuel-system2.jpeg| | + | |

| − | This shows the possible standpipe drain design for the low point of the system since no gascolator is being used. | + | [[File:Fuel-system2.jpeg|frame|This shows the possible standpipe drain design for the low point of the system since no gascolator is being used.]] |

Latest revision as of 10:55, 30 October 2017

The fuel plumbing for an EFII system is distinctly different from that of a gravity feed type system found in carbureted engines.

EFII requires high pressure fuel pumps which circulated fuel in a constant loop from tanks to feed rail and back to tanks. This keep fuel cool by shedding heat picked up while traveling through the engine compartment.

To resolve:

- Use low point standpipe drains for supply lines coming from tanks?

- Fuel pump module location: Firewall?

- Line routing for filters, etc.

Potential designs: