Difference between revisions of "Wing Fuel Tank Covers"

m |

m |

||

| Line 1: | Line 1: | ||

| + | |||

==Aux Tank Covers== | ==Aux Tank Covers== | ||

Notes from schu: | Notes from schu: | ||

| + | This method produced perfectly flat covers with the much better #8 screws at reasonable cost. | ||

| − | + | [[File:Aux fuel tank cover.jpg|800px|frameless]] | |

You need #8 nutplates (K1100-08) They are .77 each at ACS, but if you buy 300 they go down to .62 or $186. | You need #8 nutplates (K1100-08) They are .77 each at ACS, but if you buy 300 they go down to .62 or $186. | ||

Latest revision as of 09:25, 2 September 2025

Aux Tank Covers

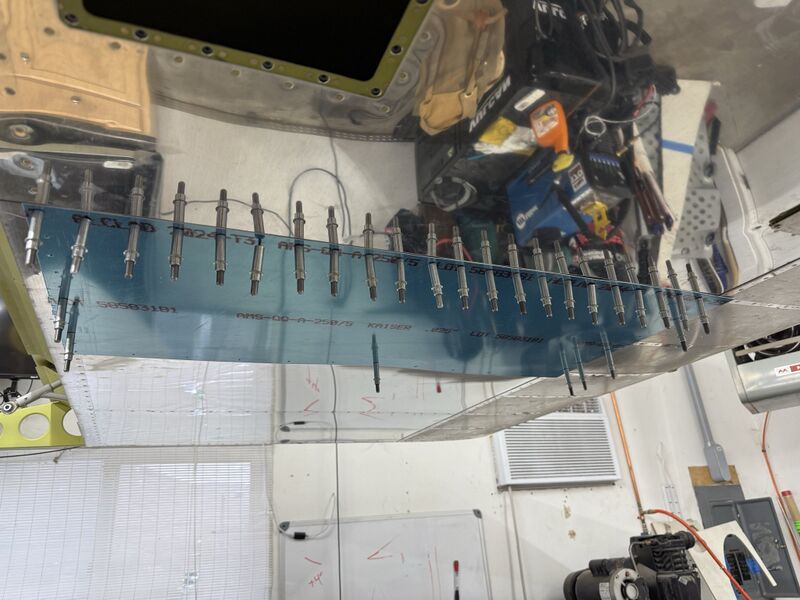

Notes from schu: This method produced perfectly flat covers with the much better #8 screws at reasonable cost.

You need #8 nutplates (K1100-08) They are .77 each at ACS, but if you buy 300 they go down to .62 or $186.

You need a #8 screw jig https://www.aircraftspruce.com/catalog/topages/twolugwingjig.php

You need a pack of new #19 and #40 drill bits

You need a #40 strap duplicator https://www.aircraft-tool.com/Detail?id=61-12

You need a #40 deburr tool https://www.yardstore.com/texas-in-out-deburr-tool-3-32

You need at least 100 silver clecos and 50 black clecos

You need a counter sink tool. I used a microstop https://www.aircraftspruce.com/catalog/topages/micro-stop.php?clickkey=5398

Cut out the blank. I used a step drill for the corners, then I used masking tape to make edges, then a right angle cutoff wheel to cut the panel 1/16" next to the rib flange, then file/sand to fit.

Now Drill out every other rivet. Use a snap punch to enlarge the divot then drill. It's not hugely important that you snap the heads off and protect the existing holes since they will be enlarged. Cut the panel, I used 15 1/2 by 33 1/16. Then mark where it goes on the wing. Tape it in place, then use the duplicator to drill every other hole trying to keep it as flat as possible.

Once the panel can be clecoed in place with every other hole, then remove, drill the other holes, then duplicate those holes. The idea is to only do half at a time so the rivets or nutplates keep everything lined up.

At this point you should have the panel lay flat with #40 holes. Now switch to #19 holes for every other hole. Replace the silver clecos with black.

Do the second set now. You should end up with #19 holes all around with everything perfectly flat.

Now use the nutplate jig to drill all of the #40 holes. Now deburr everything really well. The little tool above makes this a lot faster.

Once you have all of the holes drilled, you need to countersink all of the rivet holes.

Now dimple every #19 hole with a #8 screw dimple. Now you are finally ready to rivet all of the nutplates in place.

It took me a solid week to do the 4 tank covers.