Difference between revisions of "Extended baggage"

m |

m |

||

| (One intermediate revision by the same user not shown) | |||

| Line 52: | Line 52: | ||

[[File:Cable redirect.jpg|800px|frameless]] | [[File:Cable redirect.jpg|800px|frameless]] | ||

| + | |||

| + | ''So, the bellcrank just aft of the stick assembly is offset because the factory setup had a longer throw on one side because the cables were not 90* to the elevator horns | ||

| + | |||

| + | ''When I moved the cable one more station aft, I had two problems, the front bellcrank offset wasn't correct, and the top cable touched the the elevator at full throw.'' | ||

| + | |||

| + | ''The solution is the intermediary pulley which solves both. I didn't just set the angle to match the stock setup (though that probably would have worked) I moved it up and down and found where the cable tension was the most consistent through the entire throw.'' -Schu | ||

Latest revision as of 13:37, 30 April 2025

Contents

Motivation

The Bearhawk has great potential to be a hauler of large cargo, even more so than as-designed. To haul e-bikes or 500 gallons of popcorn, it definitely increases the utility of the aircraft by creating a positively cavernous baggage area. Another Bearhawk builder friend identified the opportunity to create the ultimate extended baggage and completed this mod. Visual evidence:

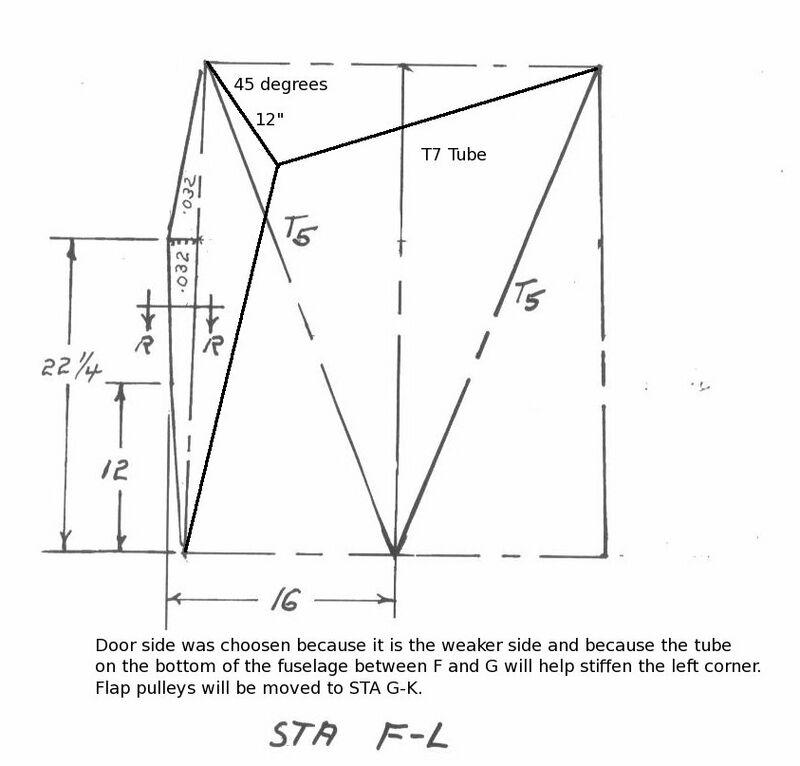

This documented and approved modification to the Bearhawk fuselage removes the "V" tubes at the flap cable "Y" split station and replaces them with an inverted dog-leg structure, which allows a large pass-through area. This makes is easier to haul long or bulky items, or even for a person to sleep in the fuselage with the rear seat removed. It necessitates moving the flap "Y" cable routing one station rearward, as well as another pulley bank. Care should be taken to limit weight at this station for CG considerations, however.

The modification is approved by Bearhawk designer Bob Barrows.

Tasks

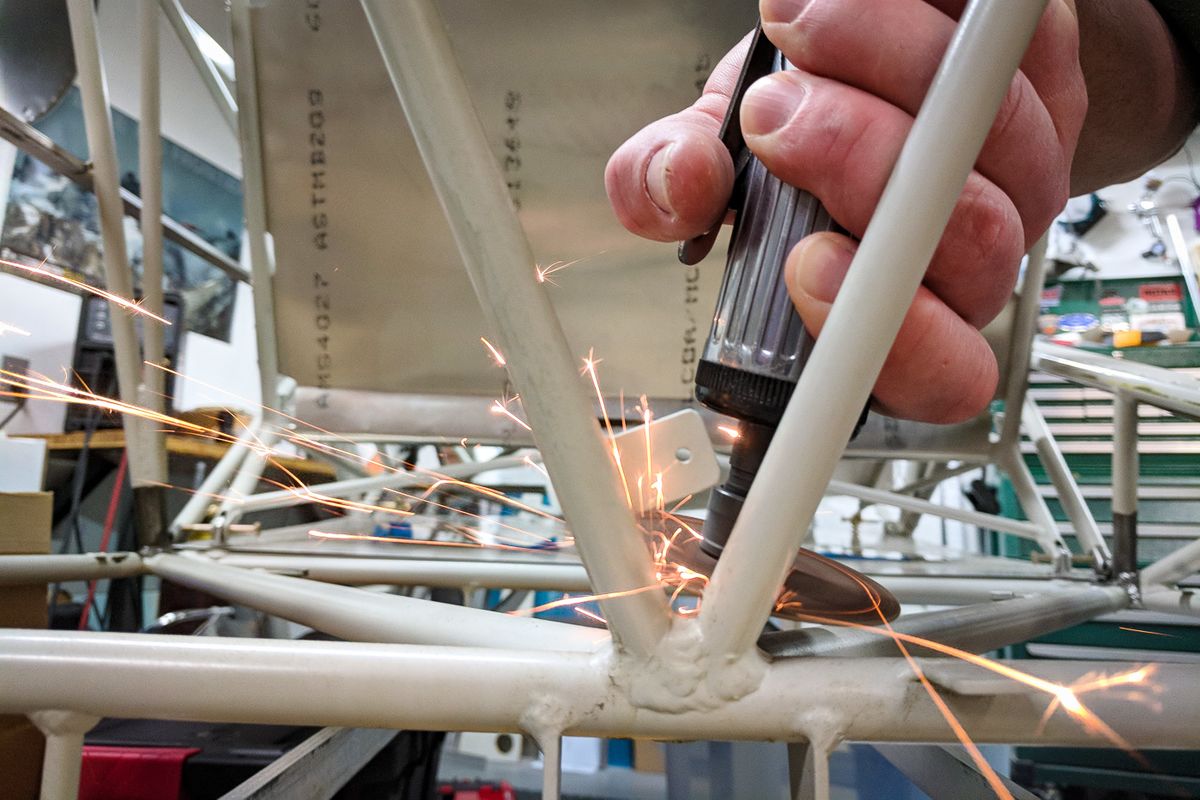

- Cut out the V-tubes - DONE

- Clean up the remnants of V tubes and welds - PARTIALLY DONE

- Build and weld in dog-leg structure and add new diagonal tubing members in floor - TO DO

- Build new pulley bank for next station aft - TO DO

- Build pulley bracket for elevator cable redirect - TO DO

- Build and weld on new fairleads - TO DO

- Build and weld on new flap pulley bushings - TO DO

1. Cutting

2. Clean up

The flap pulley bushings must be moved.

Remnants will be ground off and smoothed out. A new fairlead will be added here to route the cable.

3. Dog Leg Structure and Floor Support Tubes

The existing tube structure in the floor of the area aft of the dog leg bulkhead only uses a single diagonal 3/4" tube. Adding a full "X" structure to support the floorboard and stiffen the fuselage, making up for the weak cargo door support is a good idea. See first photo above.

4. Add Pulley Bank

This pulley bank is secured in a different way. Here's a DXF File of the pattern to cut out and bend to fit.

5. Add Pulley Bracket for Elevator Cable Redirection

This bracket and pulleys changes the angle of the cable run to even out the elevator cable tensions. My friend included a DXF file for the weld-on bracket.

So, the bellcrank just aft of the stick assembly is offset because the factory setup had a longer throw on one side because the cables were not 90* to the elevator horns

When I moved the cable one more station aft, I had two problems, the front bellcrank offset wasn't correct, and the top cable touched the the elevator at full throw.

The solution is the intermediary pulley which solves both. I didn't just set the angle to match the stock setup (though that probably would have worked) I moved it up and down and found where the cable tension was the most consistent through the entire throw. -Schu