Difference between revisions of "Bearhawk N813Z Build Reference"

m |

m (→Wings) |

||

| (15 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

[[File:Aug2015-rear-seats-5.jpg]] | [[File:Aug2015-rear-seats-5.jpg]] | ||

| + | This wiki is mainly to keep personal build notes. My Bearhawk is a 2007-era quickbuild kit from Avipro. I began my project in January 2014. In order to have the airplane I want, I've decided to do many modifications to the original design. | ||

| − | + | <div style="background:#d7e9fc;padding:12px;"> | |

| + | '''Update November 2023''': In October 2020 we pulled up anchor from Oregon and moved to northern Minnesota. This put the project into an indeterminate status where it was just stored in a hangar in Oregon. That, combined with a focus on getting my other aircraft (a tailwheel Pacer) flying, has caused more delay. | ||

| − | = Fuselage | + | I will continue using this wiki for my main log and build notes. In the meantime I am focusing on the restoration of [https://n6956b.bushplanelab.com N6956B] |

| + | </div> | ||

| + | = Fuselage = | ||

{{Status}} | {{Status}} | ||

| Line 10: | Line 14: | ||

= Wings = | = Wings = | ||

| − | + | * [[Wing Attach|Notes on wing alignment and attach drilling]]. | |

| + | * [[Fuel Tanks|Modified fuel tank filler necks]] | ||

| + | * [[Aux Fuel Tanks|Aux Tanks Install]] | ||

= Engine = | = Engine = | ||

| Line 19: | Line 25: | ||

{{Electrical}} | {{Electrical}} | ||

| + | |||

| + | = Instrument Panel = | ||

| + | |||

| + | {{InstrumentPanel}} | ||

| + | |||

| + | = Interior = | ||

| + | |||

| + | {{Interior}} | ||

| + | |||

| + | = Exterior = | ||

| + | |||

| + | Considerations here are fabric & paint system, and of course paint scheme. [[Exterior|More...]] | ||

| + | |||

| + | = Vendors = | ||

| + | |||

| + | {{Vendors}} | ||

| + | |||

| + | = Regulatory = | ||

| + | |||

| + | {{Regulatory}} | ||

Latest revision as of 16:33, 3 September 2025

This wiki is mainly to keep personal build notes. My Bearhawk is a 2007-era quickbuild kit from Avipro. I began my project in January 2014. In order to have the airplane I want, I've decided to do many modifications to the original design.

Update November 2023: In October 2020 we pulled up anchor from Oregon and moved to northern Minnesota. This put the project into an indeterminate status where it was just stored in a hangar in Oregon. That, combined with a focus on getting my other aircraft (a tailwheel Pacer) flying, has caused more delay.

I will continue using this wiki for my main log and build notes. In the meantime I am focusing on the restoration of N6956B

Contents

Fuselage

Mods status

List of mods/status/opinion/to-do:

- Skylight -- Needs finish welding

- Profiled horizontal stabilizer using wood rib extensions -- Rib extensions arrived from akschu

- non-servoing electric elevator trim using a BristolSG servo -- Mounting brackets design with Hogan and cut

- Gullwing-style seaplane doors

- Float fittings -- Undetermined route

- Additional grab handles on upper longerons forward of horz stabilizer -- Purchased Maule handles

- Straightened the profile of the back stringers to be straight by adjusting saddle heights

- Tail beef-up with vertical members -- On the fence

- Tail belly pan with stringer termination crossbar -- To do

- Extended baggage -- Now known as the "Schubag" mod -- In process

- Shoulder harness mods -- Additions to the fuselage to route shoulder harness and attach inertial reel

Wings

Engine

Lycoming IO-540-C4B5 Serial #: L-15798-48

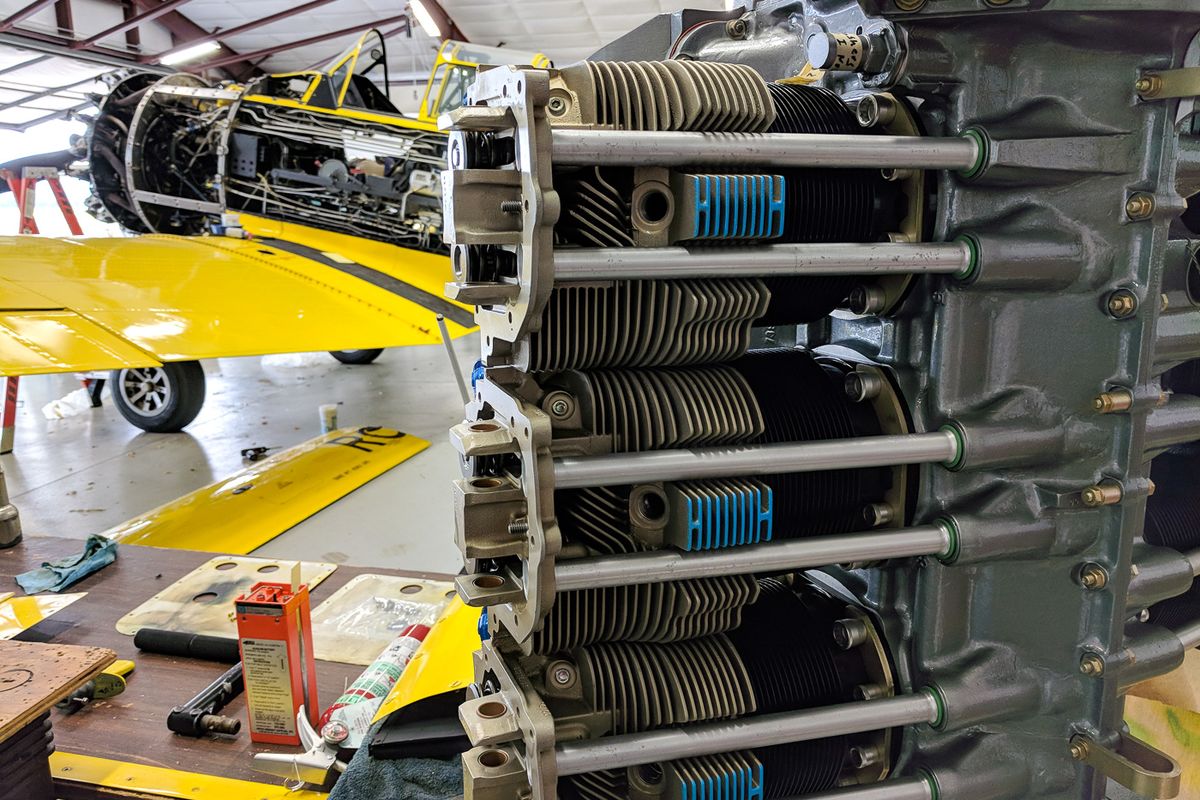

Parallel valve, narrow deck engine core as it arrived from Wentworth Aviation in Minnesota. Ready to disassemble.

Lycoming IO-540-C4B5 Serial #: L-15798-48

Parallel valve, narrow deck engine core as it arrived from Wentworth Aviation in Minnesota. Ready to disassemble.

Here's my Flickr photo gallery. I'll move pics over here when topics require.

Rebuild

I have rebuilt this core engine after it suffered a prop strike during a gear-up landing in a Piper Aztec in 2014. Nearly every component of the bottom end was in good serviceable condition save for the crankshaft, which was cranked at an oil cross tube. Replacement crankshaft is from a O-540-F1A5 out of a Robinson R-44.

This has been the most thorough and complete task of the Bearhawk build thus far.

To do:

- Bolt cylinders on - DONE

- Install oil drain-back nipples in case - DONE

- Install idler gears - DONE

- Determine which gears are being omitted from accessory case - DONE

- Clean pushrods in Graham's parts washer - DONE

- Powdercoat intake tube clamps or find machined new ones - DONE

- Cut new intake pipe hose into 1.75-2.00" sections

- Constant pressure clamp pliers

- Rocker covers, gaskets, hardware - INSTALLED

- Intercylinder baffles - INSTALLED

Ignition and injection

Plan is to use FlyEFII System32.

To do:

Lycoming resources

| File name | Type | Size |

|---|---|---|

| Lycoming overhaul manual | 15.2 MB | |

| IO-540 Parallel Valve Narrow deck IPC | 7.6 MB |

Electrical

Engine related

Lighting

Wire and components BOM

| Purpose | Wire spec | Size | Feet | Acquired |

|---|---|---|---|---|

| Starter wire | M22759/16-4-9 | 4 | 20 | Yes |

| Bus manager supply | M22759/16-10-9 | 10 | 20 | Yes |

| Main ground | M22759/16-8-9 | 8 | 10 | No |

Instrument Panel

I decided to make my instrument panel from carbon fiber, primarily to avoid riveting angle to the profile of the aluminum version. I like the Super Cub style panels that have a formed flange for which to attach the glare shield and boot cowl. The best way to do this was to do it with carbon fiber because it can be molded.

I build my mold from 3/4" MDF and used 2 layers. The top has the cutout shape of the panel. I used Bondo to form a fillet around the perimeter, and sanded it smooth, then primed and wet sanded. The next step is a glossy top coat to get the best carbon layup finish.

All Garmin panel...getting excited.

Panel layout

This is TBD.

Panel Construction

Because I want a smooth, filleted flange atop the panel like a die-pressed factory Cub panel for attaching the glareshield, I figured one way to make that happen is to use carbon fiber. I created a mold from MDF based on the kit panel shape and added a 1/4" fillet with Bondo. I then routed it with a rounded 1/4" bit to make a perfect fillet. Several coats of primer and wet sanding to get a smooth finish, and I have a nice mold.

The next step would be using a vacuum infusion method to press the carbon fiber layup.

Some years later though, with the advent of easy laser cutting, I've determined that it's hard to beat an aluminum panel and will likely just go that route, using 6061 and welding my flange on instead of giving up 1/2" to use riveted angle.

Interior

Exterior

Considerations here are fabric & paint system, and of course paint scheme. More...

Vendors

Coating

https://www.allresistantcoatings.com/

Wiring

Regulatory

N-number

Reserved N813Z — March 2023 Reserved N808ZX — February 2024

Builder's log

This wiki should become the builder's log.

To do:

- Add more photos of milestone actions

- Outline departures from standard BH build