Difference between revisions of "Elevator trim"

m |

m |

||

| (One intermediate revision by the same user not shown) | |||

| Line 1: | Line 1: | ||

| − | + | This page describes planned changes and progress to the elevator trim system. | |

| + | |||

| + | == Change To Electric Trim == | ||

| + | |||

| + | The Bearhawk uses a cable-operated trim system that actuates full-servoing trim tabs on each elevator. In my experience, the system is overly sensitive and awkward to use. I will never understand why the designer didn't opt for a flying tail type trim like a Skywagon or Super Cub. | ||

| + | |||

| + | In coordination with a fellow builder, I've opted to change to an electric trim that actuates the same trim tabs, but non-servoing. This changes to feel to something more like a standard 172. It adds an electric trim servo to each elevator. | ||

| + | |||

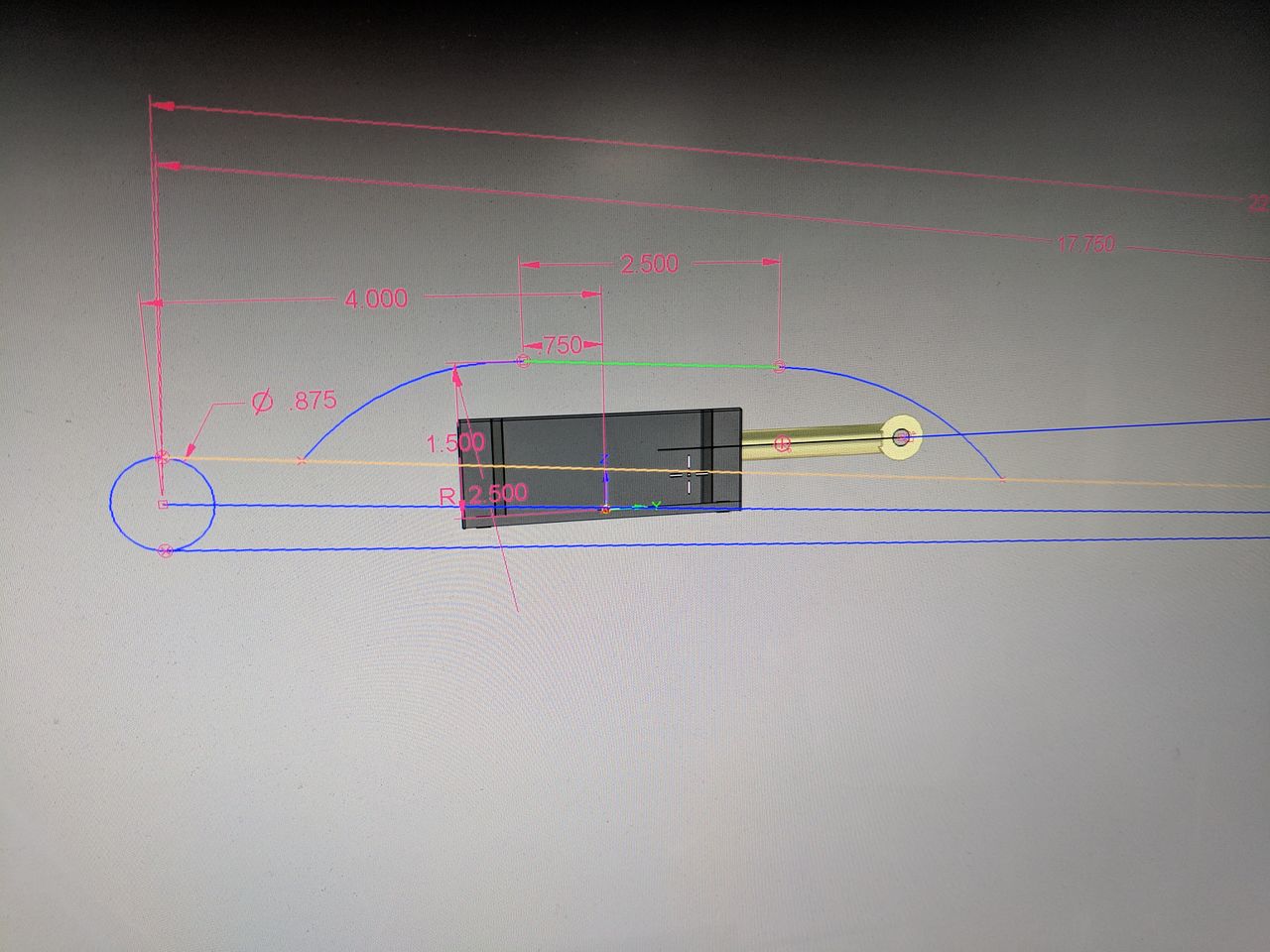

| + | A simple bracket to which to mount the electric trim servo on the underside of the elevator. Composite blister style fairing will cover the recessed servo. A push rod will emerge through a slot in the fairing and attach to the control horn on the trim tab. | ||

[[File:Servo mount.jpg|1280px|frameless]] | [[File:Servo mount.jpg|1280px|frameless]] | ||

Latest revision as of 06:30, 22 May 2024

This page describes planned changes and progress to the elevator trim system.

Change To Electric Trim

The Bearhawk uses a cable-operated trim system that actuates full-servoing trim tabs on each elevator. In my experience, the system is overly sensitive and awkward to use. I will never understand why the designer didn't opt for a flying tail type trim like a Skywagon or Super Cub.

In coordination with a fellow builder, I've opted to change to an electric trim that actuates the same trim tabs, but non-servoing. This changes to feel to something more like a standard 172. It adds an electric trim servo to each elevator.

A simple bracket to which to mount the electric trim servo on the underside of the elevator. Composite blister style fairing will cover the recessed servo. A push rod will emerge through a slot in the fairing and attach to the control horn on the trim tab.

ECU for trim

Per @akschu, using the Rugged MEGA-ET. This is an extended temp range model with better more rugged specs than the Arduino equivalent.

Bristol SG servo integrated position sensor can be read by its I/O pins.

For driving the servo motors with the MEGA, a motor driver sub board is required: https://www.pololu.com/product/2519